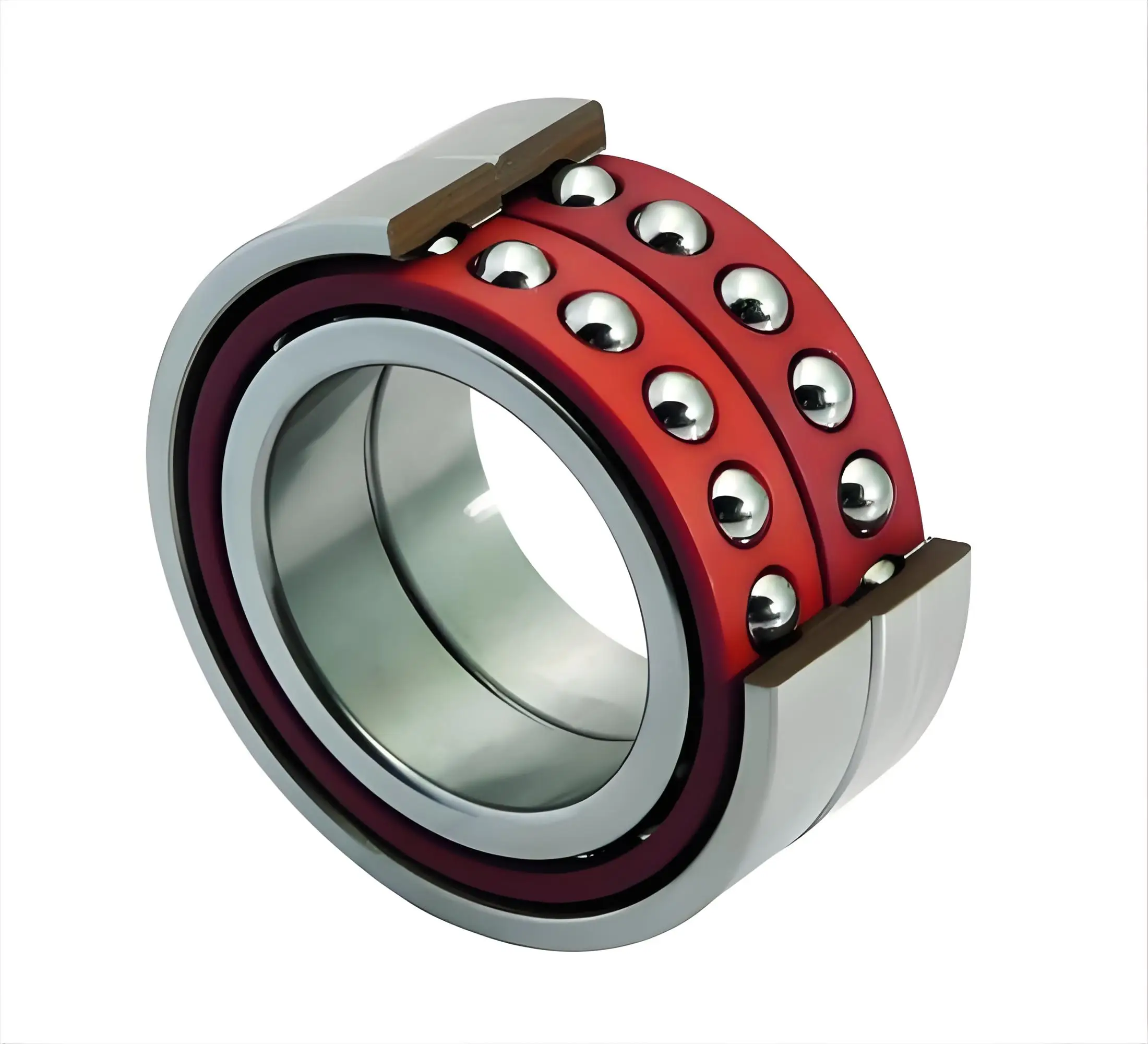

Structure:

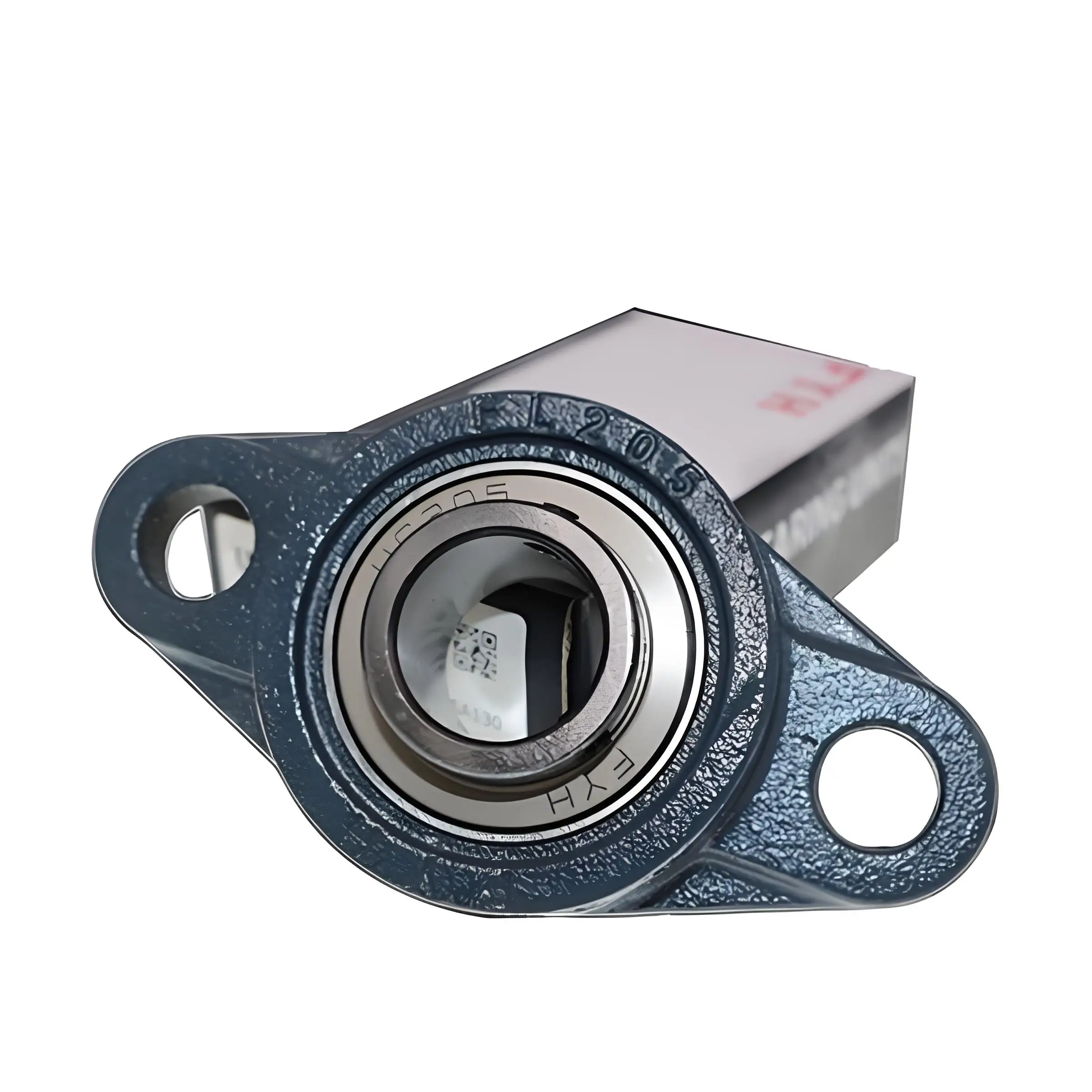

A typical ball bearing consists of the following components:

1. Inner Race (Inner Ring): The inner part that fits onto the rotating shaft.

2. Outer Race (Outer Ring): The outer part that is fixed in place, such as in a housing.

3. Balls: Spherical elements that roll between the inner and outer races, reducing friction.

4. Cage (Separator): A structure that holds the balls in place and ensures they are evenly spaced, allowing free and smooth movement.

A typical ball bearing consists of the following components:

1. Inner Race (Inner Ring): The inner part that fits onto the rotating shaft.

2. Outer Race (Outer Ring): The outer part that is fixed in place, such as in a housing.

3. Balls: Spherical elements that roll between the inner and outer races, reducing friction.

4. Cage (Separator): A structure that holds the balls in place and ensures they are evenly spaced, allowing free and smooth movement.

Working Principle:

When the inner race rotates, the balls roll along the inner surface of the outer race. This rolling motion significantly reduces friction compared to sliding motion, leading to increased efficiency and reduced wear.

Applications of Ball Bearings:

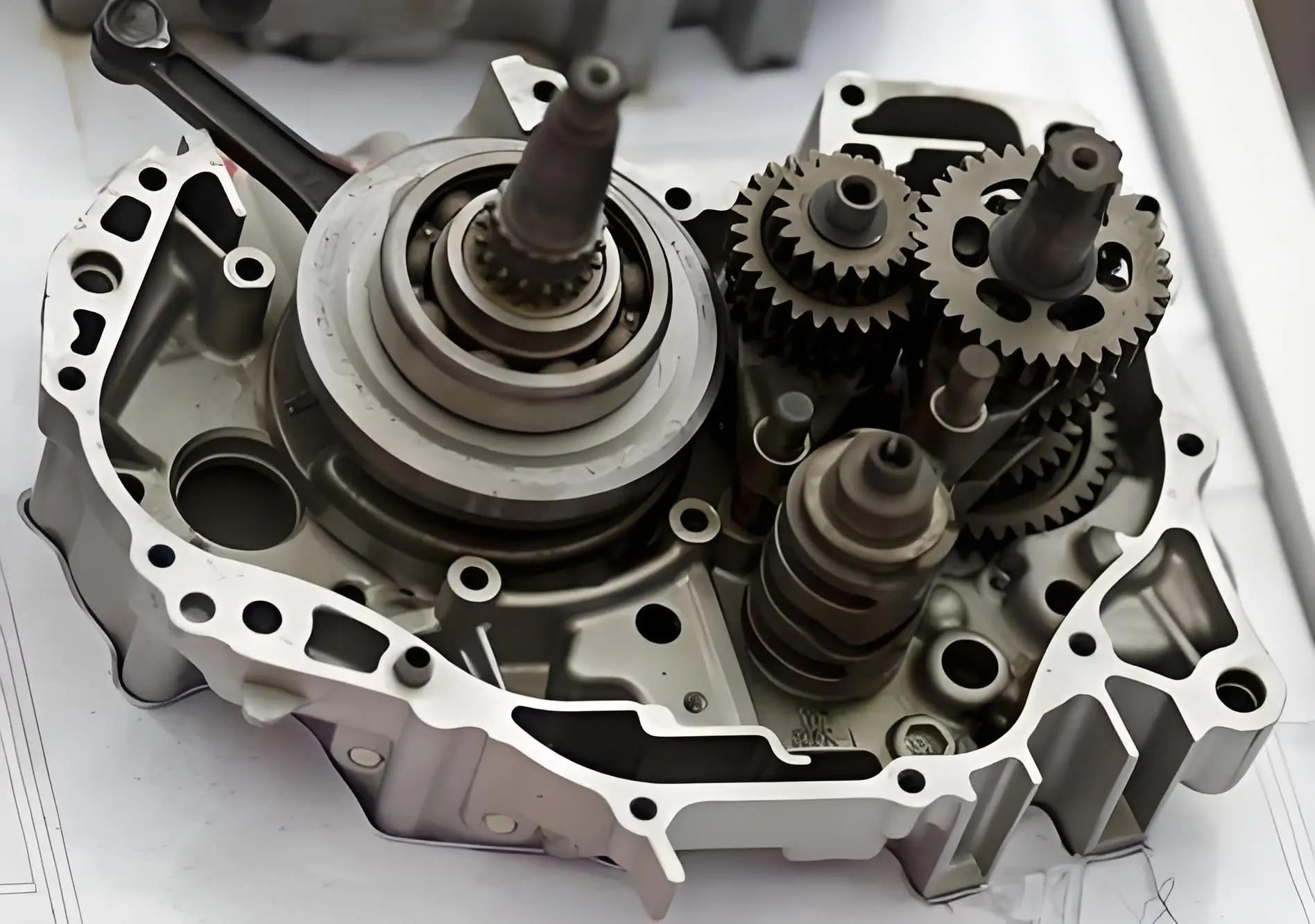

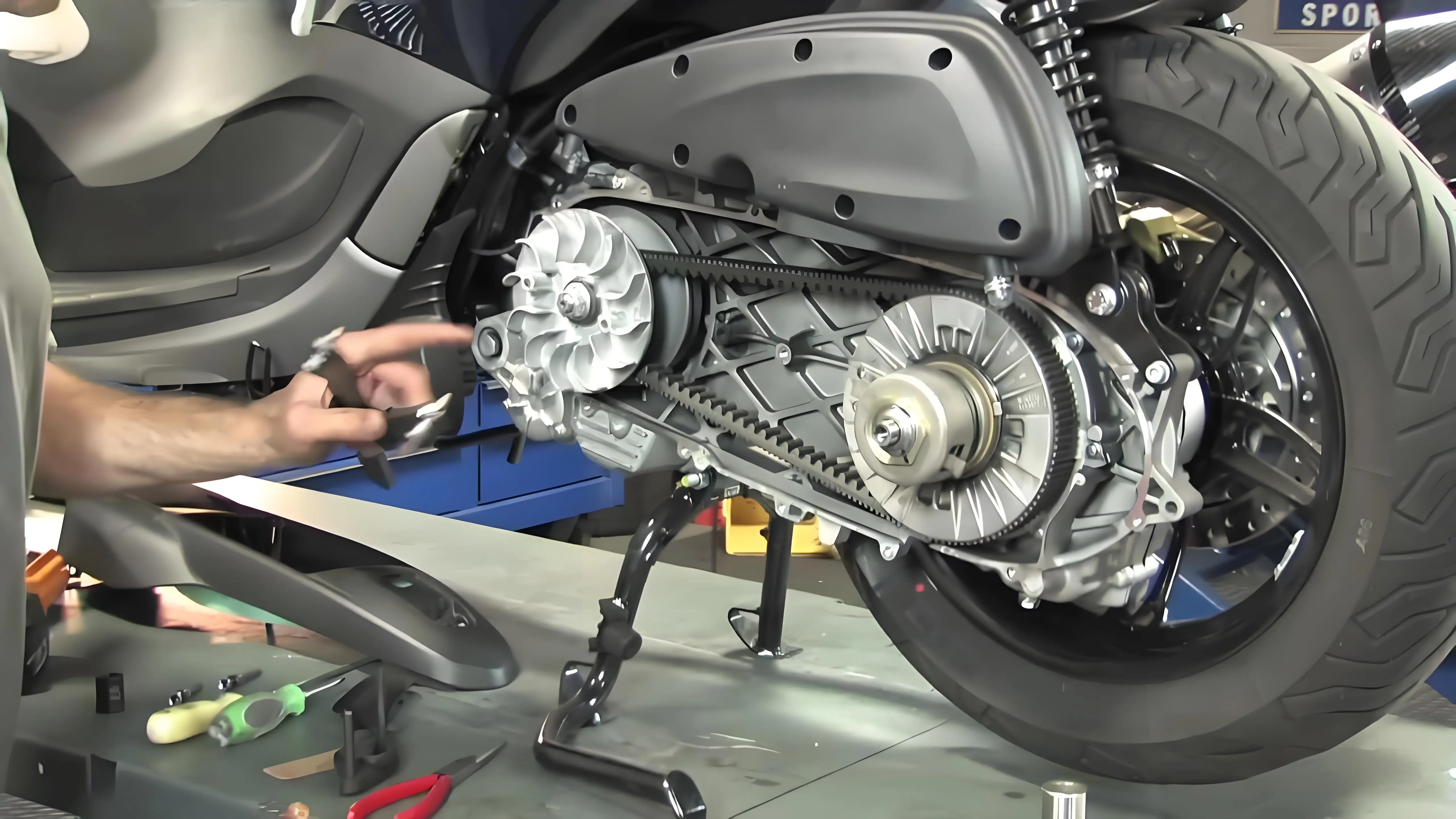

1. Automotive Industry:

* Used in engines, transmissions, wheels, and electric motors to improve performance and reduce wear.

* Found in alternators, water pumps, and starters.

2. Industrial Machinery:

* Essential in various types of machinery, including conveyors, pumps, compressors, and gearboxes.

* Used in manufacturing equipment such as CNC machines and lathes.

3. Aerospace:

* Employed in aircraft engines, landing gear, and control surfaces for reliable performance under extreme conditions and loads.

* Used in various aerospace applications where lightweight and durable bearings are crucial.

4. Electronics:

* Used in hard drives, computer cooling fans, and various small motors to ensure smooth operation and longevity.

* Found in power tools and household appliances to reduce operational noise and increase efficiency.

5. Home Appliances:

* Utilized in washing machines, refrigerators, and air conditioning units to decrease friction and improve energy efficiency.

* Found in ceiling fans and other rotating devices for smooth performance.

6. Sports Equipment:

* Incorporated into bicycles, skateboards, inline skates, and other sporting goods to enhance performance and reduce friction.

7. Medical Devices:

* Used in imaging devices like MRI machines, surgical instruments, and dental equipment to ensure precise motion and reliability.

8. Robotics:

* Essential in robotic arms and actuators for smooth and precise movements, significantly impacting the performance of automated systems.

9. Maritime Applications:

* Used in ship motors, propeller shafts, and rudder systems to ensure efficient operation in harsh ocean environments.

1. Automotive Industry:

* Used in engines, transmissions, wheels, and electric motors to improve performance and reduce wear.

* Found in alternators, water pumps, and starters.

2. Industrial Machinery:

* Essential in various types of machinery, including conveyors, pumps, compressors, and gearboxes.

* Used in manufacturing equipment such as CNC machines and lathes.

3. Aerospace:

* Employed in aircraft engines, landing gear, and control surfaces for reliable performance under extreme conditions and loads.

* Used in various aerospace applications where lightweight and durable bearings are crucial.

4. Electronics:

* Used in hard drives, computer cooling fans, and various small motors to ensure smooth operation and longevity.

* Found in power tools and household appliances to reduce operational noise and increase efficiency.

5. Home Appliances:

* Utilized in washing machines, refrigerators, and air conditioning units to decrease friction and improve energy efficiency.

* Found in ceiling fans and other rotating devices for smooth performance.

6. Sports Equipment:

* Incorporated into bicycles, skateboards, inline skates, and other sporting goods to enhance performance and reduce friction.

7. Medical Devices:

* Used in imaging devices like MRI machines, surgical instruments, and dental equipment to ensure precise motion and reliability.

8. Robotics:

* Essential in robotic arms and actuators for smooth and precise movements, significantly impacting the performance of automated systems.

9. Maritime Applications:

* Used in ship motors, propeller shafts, and rudder systems to ensure efficient operation in harsh ocean environments.

Ball bearings are vital components in a wide range of applications due to their ability to reduce friction, increase efficiency, and extend the lifespan of machinery. Their versatility and effectiveness make them integral to the functioning of many mechanical systems across various industries.