| Menge (Tonnen) | 1 - 100 | > 100 |

| Vsl. Dauer (Tage) | 31 | Zu bestimmen |

|

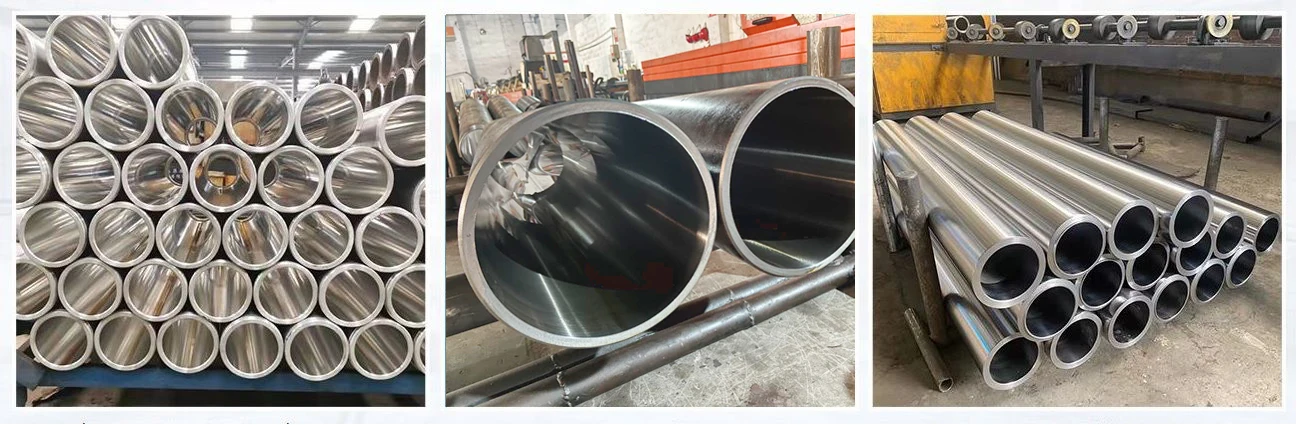

Artikel

|

Nahtloses Stahlrohr

|

|

Ursprungs ort

|

Shandong China

|

|

Markenname

|

Powersen

|

|

Abschnitt Form

|

Runde

|

|

Zertifikat

|

API, JIS, GS, ISO9001

|

|

Note

|

20 #,45 #,16Mn(ST52),25Mn, 27Simn, etc

|

|

Toleranz

|

±5%, ±1%

|

|

Standard

|

GB, DIN, EN.

|

|

Probe

|

Verfügbar

|

|

MOQ

|

1PC

|

|

Paket

|

Regelmäßige oder Kunden nicht Anforderung

|

|

Mechanische Eigenschaften

|

||||||||

|

Stahls orte

|

Zug festigkeit

Σ b N/mm²

|

Streckgrenze

Σ s N/mm²

|

Dehnung

δ %

|

Härte

HB

|

||||

|

20#

|

≥520

|

≥470

|

≥12

|

175

|

||||

|

45 #(CK45)

|

≥600

|

≥520

|

≥12

|

207

|

||||

|

16Mn(ST52)

|

≥600

|

≥520

|

≥15

|

190

|

||||

|

25Mn

|

≥600

|

≥520

|

≥15

|

195

|

||||

|

27Simn

|

≥800

|

≥720

|

≥10

|

230

|

||||

|

...

|

...

|

...

|

...

|

...

|

||||

|

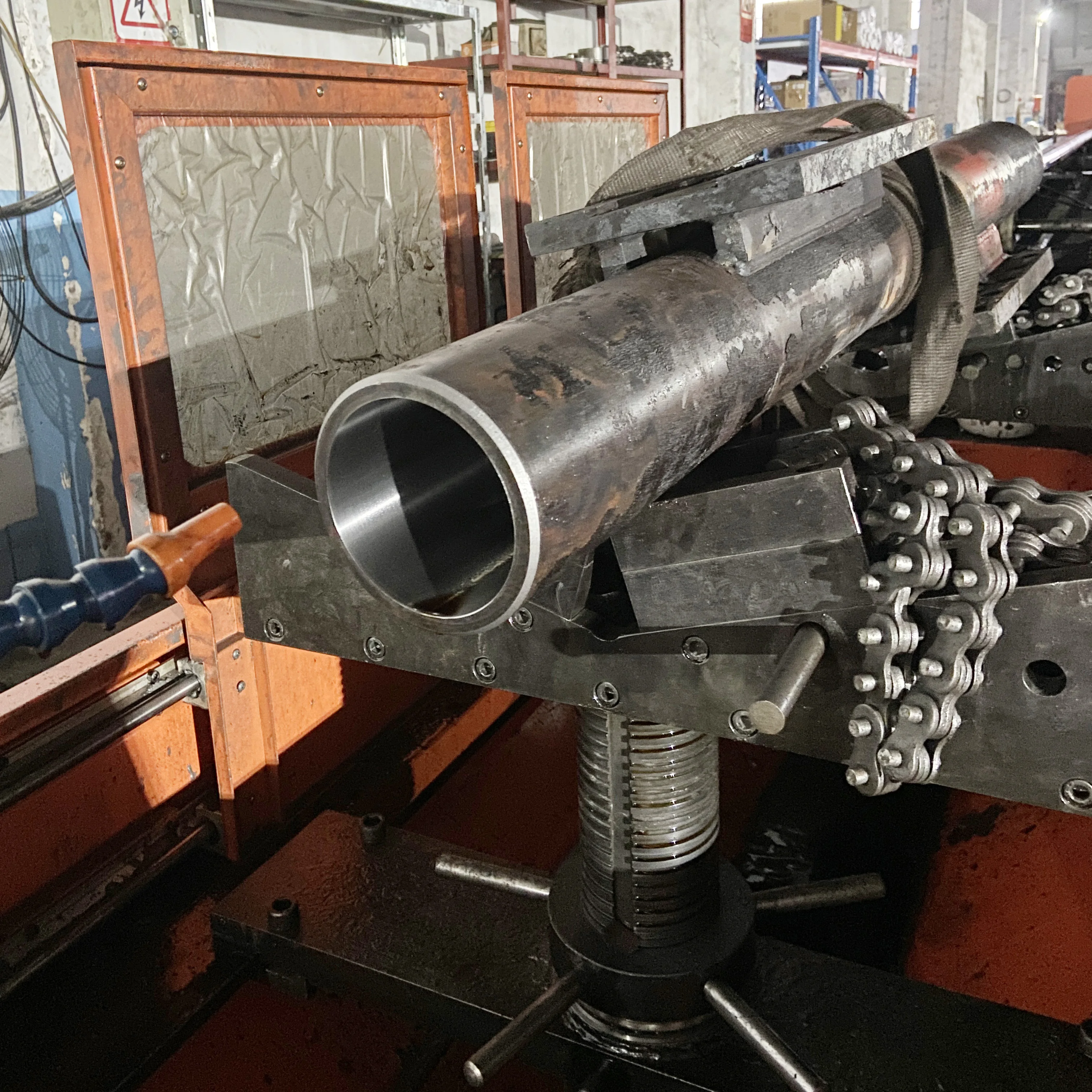

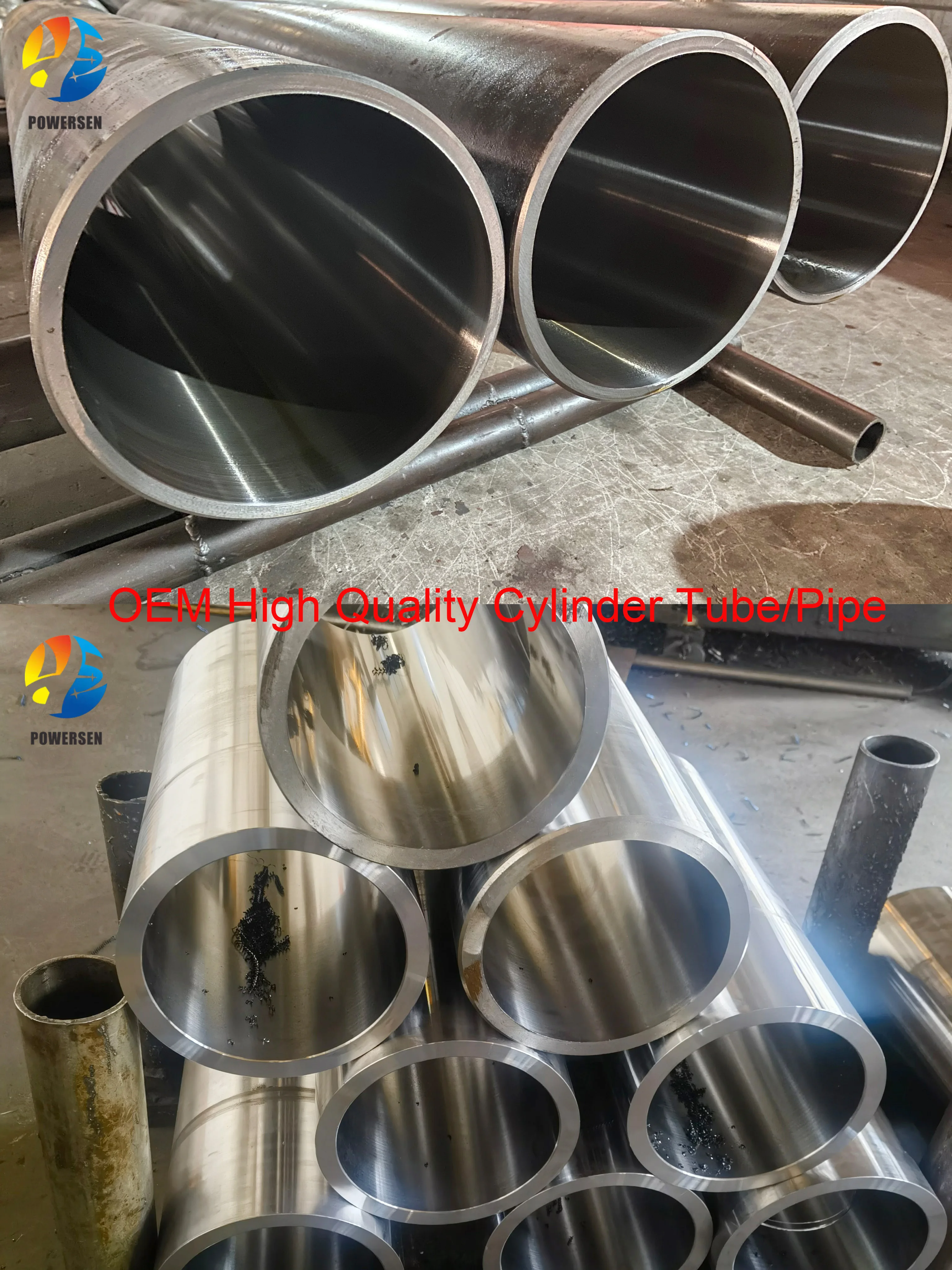

Produkt beschreibung

|

||||||||||

|

Verarbeitung formular

|

Zylinder-ID

(Mm)

|

Länge

(mm)

|

Geradheit

(Mm/m)

|

Toleranz auf Ausweis

|

Rauheit

(Μ/m)

|

|||||

|

Kalt gezogen

|

30-250

|

≤ 13m

|

0.2-0.5

|

H9-H11

|

0.8-1.6

|

|||||

|

Präzisions walzen

|

40-800

|

≤13m

|

0.2-0.3

|

H7-H9

|

0.2-0.4

|

|||||

|

Honen

|

40-800

|

≤ 7m

|

0.2-0.3

|

H7-H9

|

0.4-0.8

|

|||||

|

Brüniert

|

≤ 7m40-400

|

≤7m

|

0.2-0.3

|

H8

|

≤0.4

|

|||||

|

Größen tabelle ---Kalt gezogenes Rohr, Präzisions rohr, geschliffenes Rohr, SRB-Rohr.

Wir können Ihre Größe Rohr anpassen.

|

||||||||||||||||

|

ID

(mm)

|

OD

(mm)

|

WT

(mm)

|

Gewicht

(Kg/m)

|

|

ID

(mm)

|

OD

(mm)

|

WT

(mm)

|

Weight

(kg/m)

|

||||||||

|

35

|

45

|

5

|

4.932

|

|

90

|

108

|

9

|

21.97

|

||||||||

|

45

|

55

|

5

|

6.17

|

|

90

|

114

|

12

|

30.18

|

||||||||

|

50

|

65

|

7.5

|

10.63

|

|

100

|

110

|

5

|

12.95

|

||||||||

|

50

|

68

|

6

|

9.17

|

|

100

|

111

|

5.5

|

14.31

|

||||||||

|

50

|

70

|

10

|

14.8

|

|

100

|

114

|

7

|

18.47

|

||||||||

|

55

|

65

|

5

|

7.398

|

|

100

|

121

|

10.5

|

28.61

|

||||||||

|

56

|

68

|

6

|

9.2

|

|

100

|

127

|

13.5

|

37.79

|

||||||||

|

63

|

73

|

5

|

8.38

|

|

110

|

127

|

8.5

|

24.84

|

||||||||

|

63

|

76

|

6.5

|

11.14

|

|

110

|

133

|

11.5

|

34.46

|

||||||||

|

63

|

80

|

8.5

|

15

|

|

110

|

140

|

15

|

46.24

|

||||||||

|

63

|

83

|

10

|

18

|

|

115

|

135

|

10

|

30.83

|

||||||||

|

70

|

80

|

5

|

9.25

|

|

120

|

140

|

10

|

32.058

|

||||||||

|

70

|

82

|

6

|

11.245

|

|

125

|

137

|

6

|

19.38

|

||||||||

|

70

|

83

|

6.5

|

12.26

|

|

125

|

140

|

7.5

|

24.51

|

||||||||

|

70

|

85

|

7.5

|

14.33

|

|

125

|

146

|

10.5

|

35.09

|

||||||||

|

70

|

90

|

10

|

19.73

|

|

125

|

152

|

13.5

|

46.12

|

||||||||

|

75

|

88

|

6.5

|

13.06

|

|

130

|

159

|

11

|

38.25

|

||||||||

|

75

|

90

|

7.5

|

15.258

|

|

135

|

159

|

12

|

43.5

|

||||||||

|

75

|

95

|

10

|

20.96

|

|

140

|

159

|

9.5

|

35.03

|

||||||||

|

80

|

85

|

2.5

|

5.09

|

|

140

|

168

|

14

|

53.167

|

||||||||

|

80

|

90

|

5

|

10.48

|

|

150

|

168

|

9

|

35.29

|

||||||||

|

80

|

92

|

6

|

12.73

|

|

150

|

180

|

15

|

61.03

|

||||||||

|

80

|

95

|

7.5

|

16.18

|

|

150

|

194

|

22

|

93.31

|

||||||||

|

80

|

100

|

10

|

22.194

|

|

160

|

170

|

5

|

20.34

|

||||||||

|

80

|

102

|

11

|

24.685

|

|

160

|

180

|

10

|

41.92

|

||||||||

|

ID-Größe

(Mm)

|

ID-Toleranz

|

Toleranz der Wandstärke

|

||||||||

|

H7

|

H8

|

H9

|

H10

|

H11

|

±5%

|

|||||

|

30

|

+0.0210

|

+0.0330

|

+0.0520

|

+0.0840

|

+0.1300

|

|||||

|

>30-50

|

+0.0250

|

+0.0390

|

+0.0620

|

+0.1000

|

+0.1600

|

|||||

|

>50-80

|

+0.0300

|

+0.0460

|

+0.0740

|

+0.1200

|

+0.1900

|

|||||

|

>80-120

|

+0.0350

|

+0.0540

|

+0.0870

|

+0.1400

|

+0.2200

|

|||||

|

>120-180

|

+0.0400

|

+0.0630

|

+0.1000

|

+0.1600

|

+0.2500

|

|||||

|

>180-250

|

+0.0460

|

+0.0720

|

+0.1150

|

+0.1850

|

+0.2900

|

|||||

|

>250-315

|

+0.0520

|

+0.0810

|

+0.1300

|

+0.2100

|

+0.3200

|

|||||

|

>315-400

|

+0.0570

|

+0.0890

|

+0.1400

|

+0.2300

|

+0.3600

|

|||||

|

Zylinder lauf druckt isch

Wir können Ihre Größe Zylinder fass anpassen.

|

||||||||||||

|

ID * WT

(mm)

|

Sicherheits faktor

(N)

|

Max standhalten spannung

(MPa)

|

ID*WT

(mm)

|

Safety factor

(n)

|

Max mit Stands pannung

(MPa)

|

|||||||

|

32*4

|

3

|

48.85

|

|

110*9

|

3

|

31.97

|

||||||

|

40*2.5

|

3

|

21.25

|

|

110*11.5

|

3

|

40.83

|

||||||

|

40*5

|

3

|

48.84

|

|

110*12.5

|

3

|

44.37

|

||||||

|

40*5.5

|

3

|

53.72

|

|

110*15

|

3

|

53.21

|

||||||

|

45*4

|

3

|

34.74

|

|

120*10

|

3

|

32.56

|

||||||

|

45*5

|

3

|

43.42

|

|

120*13

|

3

|

42.30

|

||||||

|

45*6

|

3

|

52.09

|

|

125*4

|

3

|

10.88

|

||||||

|

45*7

|

3

|

65.08

|

|

125*5

|

3

|

13.6

|

||||||

|

50*2.5

|

3

|

17

|

|

125*7.5

|

3

|

20.4

|

||||||

|

50*4

|

3

|

31.27

|

|

125*10.5

|

3

|

32.82

|

||||||

|

50*5

|

3

|

39.08

|

|

125*13.5

|

3

|

42.17

|

||||||

|

50*6.5

|

3

|

50.79

|

|

125*17

|

3

|

53.05

|

||||||

Jede Zahlung auf Cooig.com ist durch strenge SSL-Verschlüsselung und PCI-Datensicherheitsstandards gesichert.

Erhalten Sie Ihr Geld zurück bei fehlenden Lieferungen oder Mängeln.